4 pillar hydraulic press machine 400T

- Description

■Four Column structure enjoys outstanding rigidity. Each press is designed through Finite Element Structural Analysis and optimization to assure high strength and rigidity.

■Adopt cartridge valve integrated system characterized by little impact, reliable movement, little leakage and long service life; Enjoy automatic lubrication system for guide rails. (Such technology is introduced from Taiwan.)

■Four columns are made of high strength alloy steel with hard chromium plated surface featuring good wear-resistance..

■The main hydraulic and electric parts adopt brand-name components from Japan, France, Germany and Taiwan, so the machineenjoys high reliable performance.

■Mitsubishi PLC +Touch Screen (HMI) integrated control. There are 3 operation manners, adjustable, manual and semi-automatic. ■Designed with adjustable drawing speed, the machine is applicable for various thickness metalworking and deep drawing.

■The press fully meets CE safety requirements.

■The slide has fast speed and high productive efficiency.

Security system:

- Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,

- The entire equipment totally security (according to EN292:1994, EN60204:1994 and NR12) and defined as Level 4 of safety.

- Intrinsic hydraulic safety valve block with redundant control and dynamic monitoring carried out by a security interface

- Right side protection: vertical door, pneumatic actuating, made of aluminium frame and polycarbonate transparate plates.

■Applications:

Deep draw press is applied in production techniques, like deep drawing, stamping, cutting, bending, flanging of metal sheet. Particularly applied in the following industries:

- Automobile Industry: steel ring, vehicle body, chasis, axle housing, fuel tank, door and many more.

- Household Appliance Industry: Components for air conditioner, refrigerator, washing machine, electric cooker etc.

- Kitchen Ware Industry: stainless steel utensil, gas cylinder, stainless steel sink, cooking bench, etc.

- Aluminum Cookware.

- Optional:

- Moving Bolster / Die Change Trolley

- Stamping Dampers for shock proof while stamping

- Trolley / Moving Bolster for easy die change

- Cushion Device for anti-shock while stamping

- Water Cooler / Oil Chiller

- Mould Hydraulic clamping

- Air breathing design as per request

- Accumulators for fast speed and low energy consumption

5. Configuration list:

| No. | Item | Standard MAKE | High Standard MAKE |

| 1 | PLC | Mitsubishi | Siemens |

| 2 | Motor | WanNan/China top brand | Siemens / Rexroth |

| 3 | Pump | Anson/Taiwan, Yuken/Japan | Siemens / Rexroth |

| 4 | Servo Pump | DAIKIN/Japan | DAIKIN/Japan |

| 5 | Directional Valve | Yuken/Japan | Atos/Italy, Rexroth |

| 6 | Proportional Valve | Yuken/Japan | Atos/Italy, Rexroth |

| 7 | Cartridge Valve | Jeou Gang/Taiwan,SUN/USA | SUN, Atos, Rexroth |

| 8 | Prefill Valve | TAI COLN/Taiwan | Atos/Italy, Rexroth |

| 9 | Electric Units | Schneider/France | Schneider/France |

| 10 | Light Curtain | LNTECH with CE Mark | LNTECH with CE Mark |

| 11 | Touch Screen(HMI) | Weinview/Taiwan | Siemens |

| 12 | Pressure Gauge | SKON/Taiwan | SKON/Taiwan |

| 13 | Hydraulic Manifold | MADE IN TAIWAN | MADE IN TAIWAN

|

6.Technical Specifications:

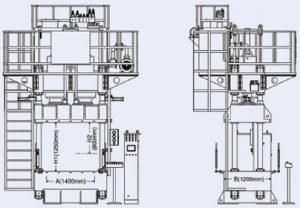

| Seri-al No. | Name | Unit | LVD-500T | |

| 1 | Press Capacity | KN | 5000 | |

| 2 | Slide Stroke | H2 | mm | 600 |

| 3 | Max. Daylight | H1 | mm | 1000 |

| 4 | Cushion Capacity | KN | 3150 | |

| 5 | Cushion Stroke | mm | 250 | |

| 6 | Down Speed | mm/sec | 350 | |

| 7 | Pressing Speed | mm/sec | 10÷25 | |

| 8 | Return Speed | mm/sec | 250 | |

| 9 | Lifting Capacity | KN | 1000 | |

| 10 | Mould Open Force | KN | 1300 | |

| 11 | Table Size(LR* FB) | A/B | mm | 1500×1500 |

| 12 | Cushion Size(LR* FB) | mm | 1250×1250 | |

| 14 | Worktable Height | -G | mm | 1250 |

| 15 | Oil Tank Capacity | L | 500 | |

| 16 | Main motor | kw | 30 | |